You need to register to access this content. Registration is free and can be done below. Alternatively, you can log in or join our membership for unlimited CPD content.

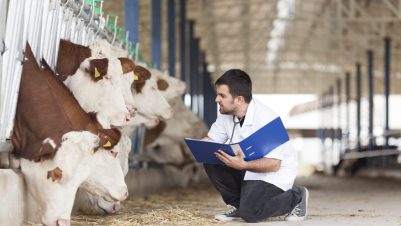

Veterinary considerations for artificial meat

Armed with a balance between scientific enthusiasm and the realities of animal production, it seems very important that veterinary surgeons consider the factors involved in the production of artificial meat as regulators and politicians will be looking for guidance